Web menu

Product Search

LENTITUDO

Exit Menu

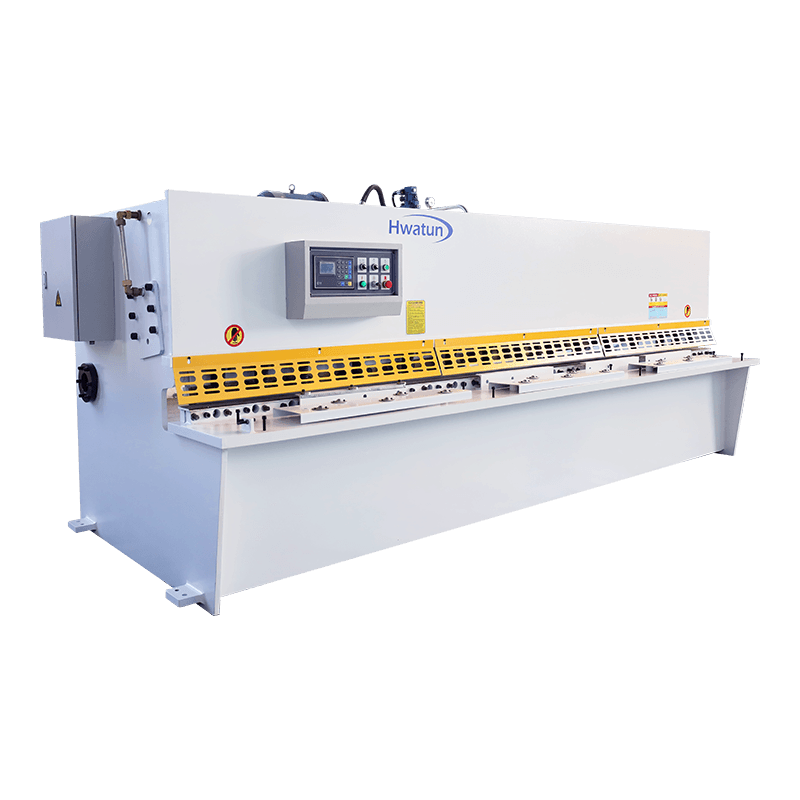

In today’s manufacturing environment, the shearing machine remains a fundamental tool for cutting metal sheets and plates with speed and precision. Whether you're working in a small fabrication shop or managing a large-scale production line, understanding how to choose and use a shearing machine effectively is crucial for maximizing efficiency, ensuring safety, and maintaining product quality.

The first step in selecting a shearing machine is identifying your specific needs. Shearing machines come in various types, including manual, mechanical, hydraulic, and CNC-controlled models. Manual shears are suitable for light-duty applications and smaller operations, while hydraulic and CNC models offer greater power, precision, and automation — ideal for high-volume or complex industrial tasks.

Equally important is understanding the machine's specifications. The maximum cutting thickness and length determine what kind of materials the machine can handle. For example, a standard benchtop shear might be sufficient for thin aluminum sheets, but heavy-duty steel plates would require a larger, more powerful machine. It's also essential to consider blade material and design, as these directly affect cut quality and machine longevity.

Safety should never be overlooked when operating a shearing machine. Due to the high forces involved, improper use can lead to serious injury. Operators must be trained in correct setup procedures, including adjusting blade clearance based on material type and thickness. Additionally, modern shearing machines often come equipped with safety features such as light curtains, emergency stop buttons, and two-hand operation controls — all of which should be used consistently to prevent accidents.

Proper maintenance is another key factor in ensuring reliable performance. Regularly inspecting and sharpening blades, lubricating moving parts, and checking hydraulic or electrical systems can significantly extend the life of the machine and reduce downtime. A well-maintained shearing machine not only performs better but also contributes to consistent output and reduced material waste.

Beyond basic operation, integrating the shearing machine into a broader production workflow can further enhance productivity. In automated environments, pairing shearing machines with loading/unloading systems or connecting them to CAD/CAM software enables seamless data transfer and minimizes human error. This level of integration is especially valuable in industries like automotive, construction, and aerospace, where tight tolerances and repeatable accuracy are critical.

Lastly, environmental and cost considerations play an increasing role in equipment selection. Energy-efficient models and machines designed for recyclable material processing can help companies meet sustainability goals while reducing long-term operational costs. Investing in a durable, adaptable shearing machine can provide significant returns over time, both in terms of financial savings and improved workflow efficiency.

Choosing and using a shearing machine effectively requires more than just knowing how to turn it on. From evaluating technical specifications and prioritizing safety to embracing automation and sustainability, understanding the full scope of shearing machine usage is essential for any manufacturer aiming to stay competitive in today’s industrial landscape.

News Categories

Product Categories

Related Products

+ 86-159 (V) CXXXVIII MCCCXVI

+ 86-159 (V) CXXXVIII MCCCXVI +LXXXVI CLXXX (VI) DCCCXIX MMMXCVI

+LXXXVI CLXXX (VI) DCCCXIX MMMXCVI

Group IV, Xinba Village, Binhai Nova Area (Jiaoxie Urbs), Laoba Portus, Nantong urbem, Jiangsu, Sinis.

Group IV, Xinba Village, Binhai Nova Area (Jiaoxie Urbs), Laoba Portus, Nantong urbem, Jiangsu, Sinis.

Copyright © Nantong Hwatun gravis machina instrumentum Co., Ltd. Omnes ligula.

简体中简体中

简体中简体中